Merchandise dispatch protocol

Use of personal protective and safety equipament, including respirator protection, gloves, closed shoes and/or aprons during operation.

Continuous hand washing at least every 3 hours or whenever necessary, and avoiding contact with eyes, nose and mouth without hand washing.

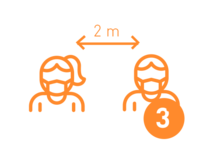

Work methods that prevent contact with other people, maintainning a distance of at least 2.0 meters during the operation and, if necessary for the activity to be executed, maintainning a reasonable distance, without putting themselves at risk during execution.

Use of cleaning agents, antibacterial gel, glycerin alcohol and/or disinfectant wipes during operation to guarantee an evironment free of potentially contaminating agents.

Regulary desinfecting contact surfaces, desk, PCs, laptops, communication equipment, mobile devices: forklifts, dockers, picking carts, and work tables, among others, using disposable wipes and taking preventive measures for such purpose.

Ensure the disinfection process of vehicles in compliance with the minimum requirements, to include tires, lower parts of the vehicle, and areas of permanent contact, among others.

The vehicle must be positioned in the merchandise loading and/or unloading designated area.

Fumigation and cleaning controls in the material receiving and/or dispatch areas, to ensure the protection mechanisms of work equipment, and using sanitizing products adjusted to the characteristics of the materials in each manufacturing facility. Once the products have been disinfected, it is recommended to leave them at least 5-10 minutes before handing, placing and/or dispatching them.

Fumigation and cleaning controls in the material receiving and/or dispatch areas, to ensure the protection mechanisms of work equipment, and using sanitizing products adjusted to the characteristics of the materials in each manufacturing facility. Once the products have been disinfected, it is recommended to leave them at least 5-10 minutes before handing, placing and/or dispatching them.

Correctly dispose of the waste generated by daily equipment operation.